Tire shredder capacity is the first number buyers ask for. It is also the easiest number to misread. A shredder can look fast in a short demo. Real tire shredder capacity comes from stable feeding, steady torque, and a shred size that matches the next machine.

1 Start with three inputs

Tire type

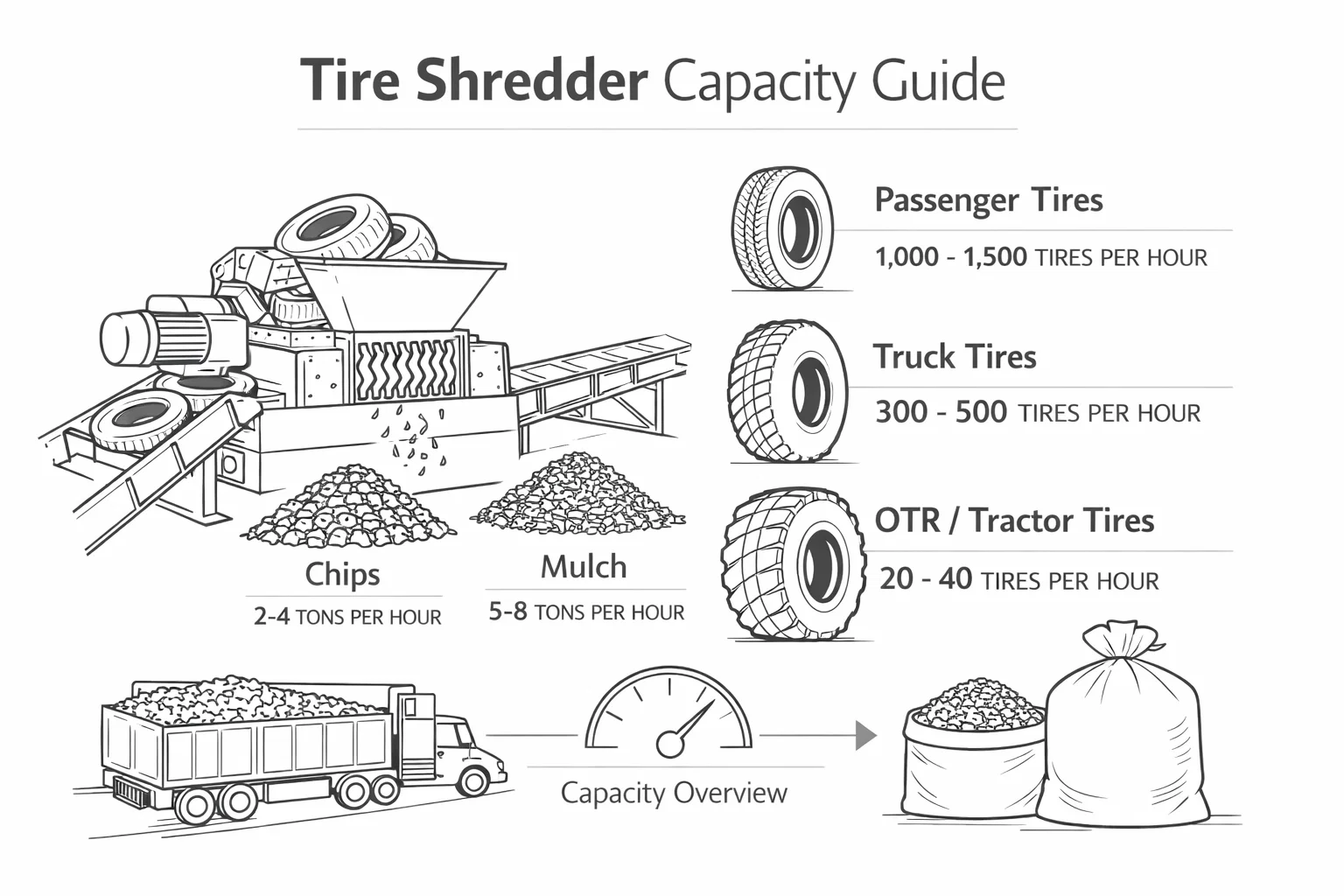

Passenger tires usually shred faster because they carry less steel and the structure is lighter. Truck tires carry more steel and thicker tread, so they need higher torque. OTR tires push this further. They often need stronger shafts, stronger gearboxes, and a feed system that keeps the cut consistent.

Target shred size

Coarse shreds for tire derived fuel and tire derived aggregate usually run faster. Smaller and more uniform chips slow the shredder because the cut repeats more times per tire. Decide shred size from your downstream plan. If you want rubber granules or rubber powder, the shredder should feed a granulator or a cracker mill smoothly.

Feed method

Feeding decides output more than most people expect. Conveyor feeding with stable speed keeps the rotor loaded. Hydraulic or mechanical forced feeding reduces bridging and helps avoid idle cutting. Irregular loading causes frequent reversals. Reversals protect the machine. They also reduce true output.

2 Ask for a capacity range, not one number

When you request a quote, ask the supplier to state tire shredder capacity as a range tied to tire type and shred size. A single number is rarely honest because the same machine behaves very differently on passenger tires versus truck tires, and even more differently on OTR tires.

Also confirm the measurement method.

- Is capacity based on continuous feeding or on batch loading

- Is it measured after the machine reaches steady operation

- Is it measured with mixed tires or with only one easy tire type

If you want to compare suppliers fairly, send the same tire mix and the same target shred size.

3 What to verify in a demo or acceptance test

Measure stable output

Record output only after the shredder reaches steady operation. Run the test long enough to include steel heavy tires and mixed sizes.

Track reversals and downtime

If the shredder reverses often, you are not seeing real capacity. You are seeing protection logic. Frequent reversals usually point to poor feeding, dull knives, wrong knife configuration, or a target shred size that forces too many cuts.

Confirm what leaves the shredder

If steel wire stays trapped in rubber shreds, the next machine slows down. Plan steel separation and confirm how the line handles wire, fiber, and dust.

4 Protect capacity with line design

Capacity drops when the shredder works alone. A complete line keeps material flow stable.

- Use a tire shredder that matches your tire mix and your target shred size

- Add conveyors and a stable feeding system so the shredder runs continuously

- Match shred size to your next machine stage

If you want a full line view, see our guide on line configuration and key modules for stable throughput and product quality.

For equipment details, see our Tire Double Shaft Shredder. For general background on scrap tire management and end uses, you can also check this industry reference: U.S. Scrap Tire Management Summary.

5 Practical rule of thumb for buyers

If you process only passenger tires and you accept coarse output, you can often reach higher tons per hour with the same frame size. If you add truck tires or OTR tires, plan for more torque, stronger knives, and better feeding. This is the safest way to protect tire shredder capacity and avoid bottlenecks.