Tire Recycling Machine: A Complete Guide to Turning Waste Tires into Profit

Every year, the world generates over a billion end-of-life tires (ELTs), creating a monumental waste management challenge. For forward-thinking manufacturers and industrial recycling operators, this challenge represents a significant opportunity. The key to unlocking this potential lies in a sophisticated and robust technology: the tire recycling machine.

Key Takeaways from This Article

- Technical Breakdown: A deep dive into the complete tire recycling process, from shredding to purification.

- Buyer’s Guide: Critical factors for selecting high-efficiency rubber recycling equipment.

- Market Value: Explore the commercial potential of recycled products like crumb rubber and steel.

- Expert Insights: Learn how Rumtoo Machine provides the technology and support for your recycling project’s success.

Why We Can’t Ignore the Waste Tire Problem

Simply landfilling used tires is not a sustainable solution. They consume valuable space, risk damaging landfill liners, and pose serious environmental and safety hazards. Increasingly strict global regulations are pushing industries toward more responsible solutions, making an investment in a tire recycling plant a sound environmental and economic decision.

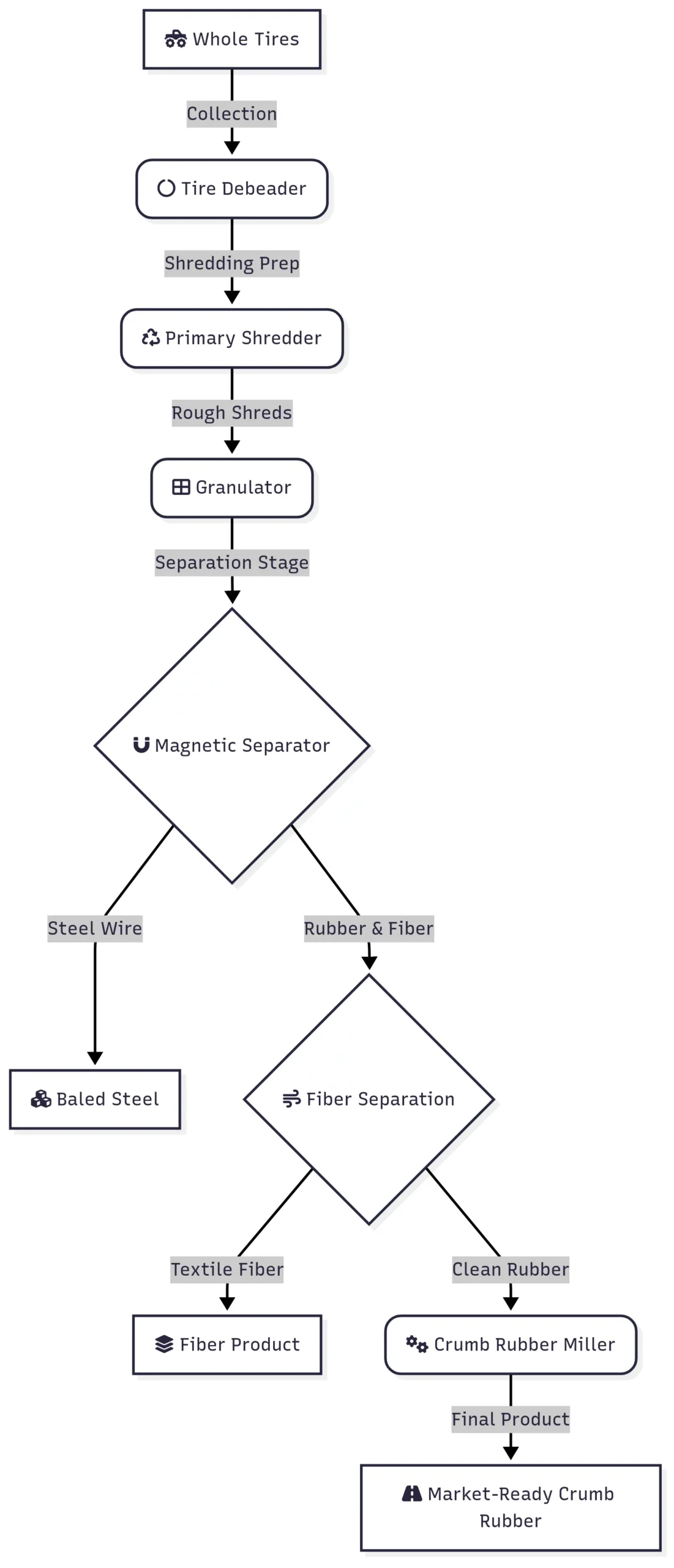

The Tire Recycling Process: A Step-by-Step Technical Breakdown

Transforming a whole tire into its constituent parts—rubber, steel, and fiber—is a multi-stage process that demands precision-engineered equipment. The solutions from Rumtoo Machine ensure every step is efficient and reliable.

Stage 1: Primary Breakdown – Debeading and Shredding

The first challenge is overcoming the tire’s immense durability. This stage involves two key actions:

- Tire Debeading: A specialized tire debeader extracts the high-tensile steel wire from the tire’s inner bead. This is crucial for protecting downstream equipment from damage.

- Primary Shredding: Debeaded tires are fed into a primary tire shredder. These high-torque, low-speed machines tear the tires into rough, 2-6 inch strips.

Stage 2: Material Liberation – Granulation and Separation

The tire strips now move to the next phase, where different materials are separated.

- Granulation & Steel Separation: The material is fed into a rubber granulator which grinds it further. Powerful magnets then pull the liberated steel wire from the rubber mixture. This recovered steel is a clean commodity that can be sold directly to steel mills.

- Fiber Separation: The remaining mix of rubber and fiber passes through a system that uses screens and air currents to separate the lighter textile fiber from the heavier rubber granules.

Rumtoo Machine Tire Recycling Plant Workflow

This diagram illustrates a standard workflow. Rumtoo Machine can customize plant layouts based on specific client requirements.

Stage 3: Refining the Rubber – Creating Crumb Rubber

The final and most valuable output is crumb rubber.

- Crumb Rubber Production: The clean rubber granules are fed into a crumb rubber machine for fine grinding. This produces a final product with a specific mesh size. The advanced equipment from Rumtoo Machine offers precise control over particle size, ensuring the output meets strict market demands.

The Valuable End Products of Tire Recycling

A modern waste tire recycling operation doesn’t produce waste; it creates a portfolio of in-demand commodities.

| Product | Market Value | Key Applications |

|---|---|---|

| Crumb Rubber | High | Rubberized Asphalt, Playground Surfaces, Athletic Tracks, Molded Rubber Products, Artificial Turf Infill. |

| Recycled Steel | Moderate | Sold to steel mills and foundries for creating new steel products. |

| Textile Fiber | Low-Moderate | Used as Tire-Derived Fuel (TDF), in certain construction materials, or as industrial absorbents. |

How to Choose the Right Tire Recycling Machine: A Buyer’s Guide

Selecting the right rubber recycling equipment is critical for your plant’s efficiency and profitability. As a buyer, consider these key factors:

- Capacity and Throughput: Evaluate your expected input volume and choose machinery that can handle your target capacity.

- Types of Tires to be Processed: Be clear about your feedstock—passenger car tires, truck tires, or OTR tires.

- Desired Output Specifications: Your end market dictates the required particle size and purity.

- Durability and Maintenance: Opt for heavy-duty equipment built with wear-resistant alloys. Rumtoo Machine prides itself on building robust equipment with exceptional after-sales support.

- Automation and Control Systems: Modern PLC control systems reduce labor costs and improve operational efficiency.

- Supplier Expertise and Trustworthiness: A partner’s experience is vital. The engineering team at Rumtoo Machine delivers complete, turnkey solutions optimized for performance and ROI.

Frequently Asked Questions (FAQ)

Is tire recycling a profitable business?

Yes, tire recycling can be very profitable. Revenue comes from tipping fees and the sale of crumb rubber, steel, and fiber. Profitability is maximized by using efficient, reliable equipment like that from Rumtoo Machine, which lowers operational costs and produces high-quality end products.

What’s the difference between a tire shredder and a granulator?

A tire shredder is a primary machine that tears whole tires into large strips (2-6 inches). A granulator is a secondary machine that grinds these strips into much smaller, uniform rubber granules (e.g., < ¾ inch). Both are critical components of a complete recycling line.

What are the main environmental benefits of using a tire recycling machine?

The key benefits are immense. Recycling conserves landfill space, prevents toxic pollution from tire fires, reduces the need for virgin materials like petroleum and iron ore, and saves a significant amount of energy compared to producing new materials from scratch.

Take the Next Step Towards a Sustainable and Profitable Future

The challenge of waste tires is undeniable, but so is the opportunity. With the right technology, end-of-life tires can be transformed from an environmental liability into a valuable asset.

Contact Rumtoo Machine for a QuoteOur team of industrial recycling specialists is ready to help you build a high-performance tire recycling plant tailored to your specific needs.