Profitable Tire Recycling Machine Solutions

Our state-of-the-art Tire Recycling Machine transforms the challenge of scrap tire disposal into a profitable business opportunity. Using advanced technology, we ensure maximum efficiency in converting waste tires into valuable recycled materials. Reduce your environmental footprint, generate new revenue streams, and enhance your operational productivity with our reliable and safe equipment.

Features for Maximum ROI

High Efficiency Grinding

Our industrial tire shredder utilizes state-of-the-art grinding technology to ensure maximum material recovery and a high yield of recycled rubber for various commercial applications.

Fully Automatic Operation

Designed for full automation, our system reduces labor costs and enhances operational uptime, allowing for continuous, 24/7 processing of scrap tires.

Space-Saving Compact Design

The compact footprint of our tire recycling plant makes it easy to integrate into existing facilities, saving valuable space while maximizing output and efficiency.

Durable & Robust Construction

Built for longevity with high-quality materials and superior engineering, our machine guarantees long-term reliability and low maintenance costs for a better return on investment.

Versatile End-Products

Our system produces a range of profitable end-products, including crumb rubber, steel wire, and tire-derived fuel (TDF), opening multiple revenue streams.

Full Environmental Compliance

Engineered to meet and exceed stringent eco-regulations, our machine ensures your operation is safe, responsible, and fully compliant with all environmental standards for tire disposal.

Key Components of the Production Line

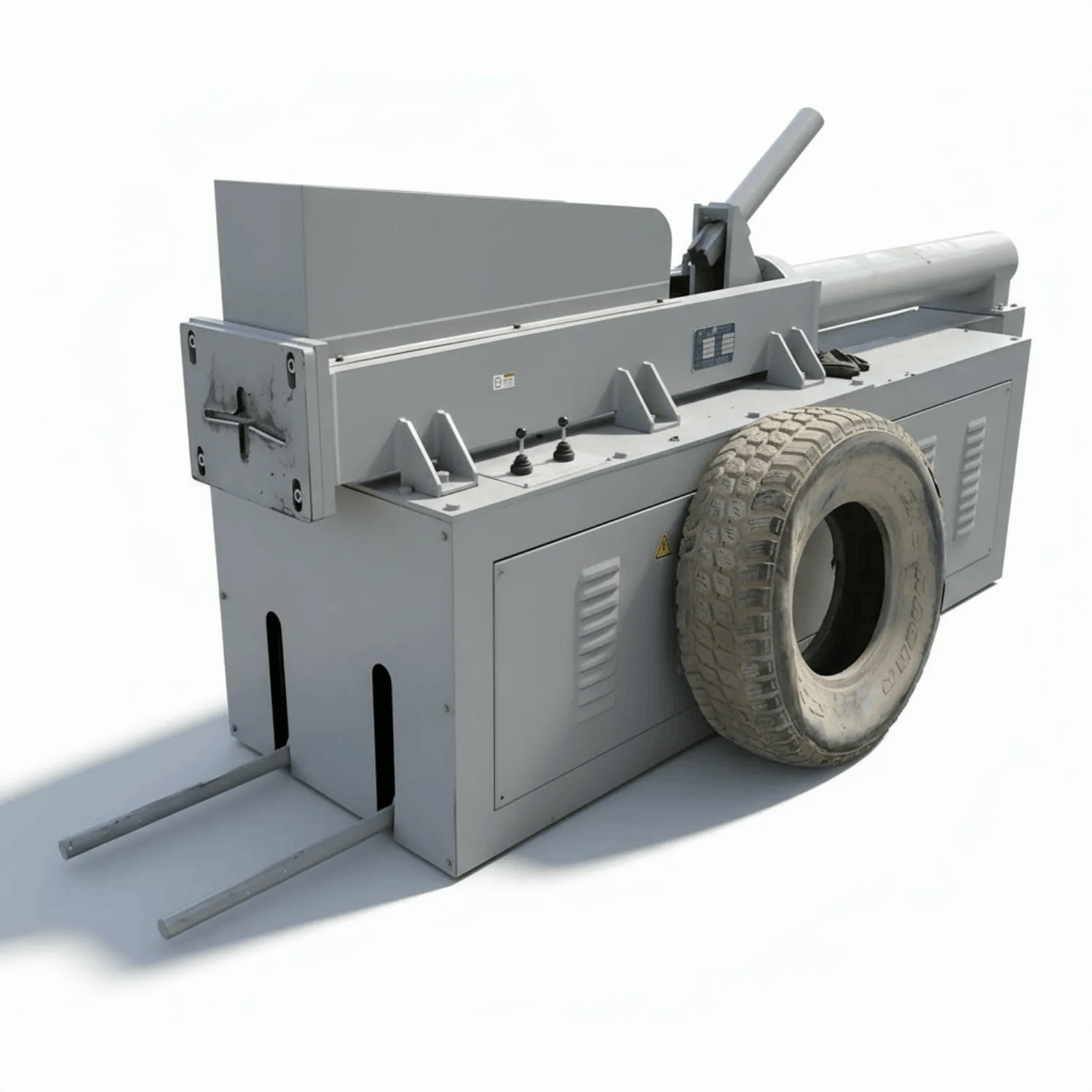

Single Hook Debeader

The Single Hook Debeader is essential pre-treatment equipment for any tire recycling line. Its primary function is to forcefully extract the tough, thick steel bead wires from waste tires before shredding. This crucial first step protects the blades of downstream shredders from significant damage and wear, which extends equipment life, reduces maintenance costs, and improves the overall stability of your operation. Furthermore, the extracted steel bead can be sold as high-value scrap, increasing the profitability of your recycling process.

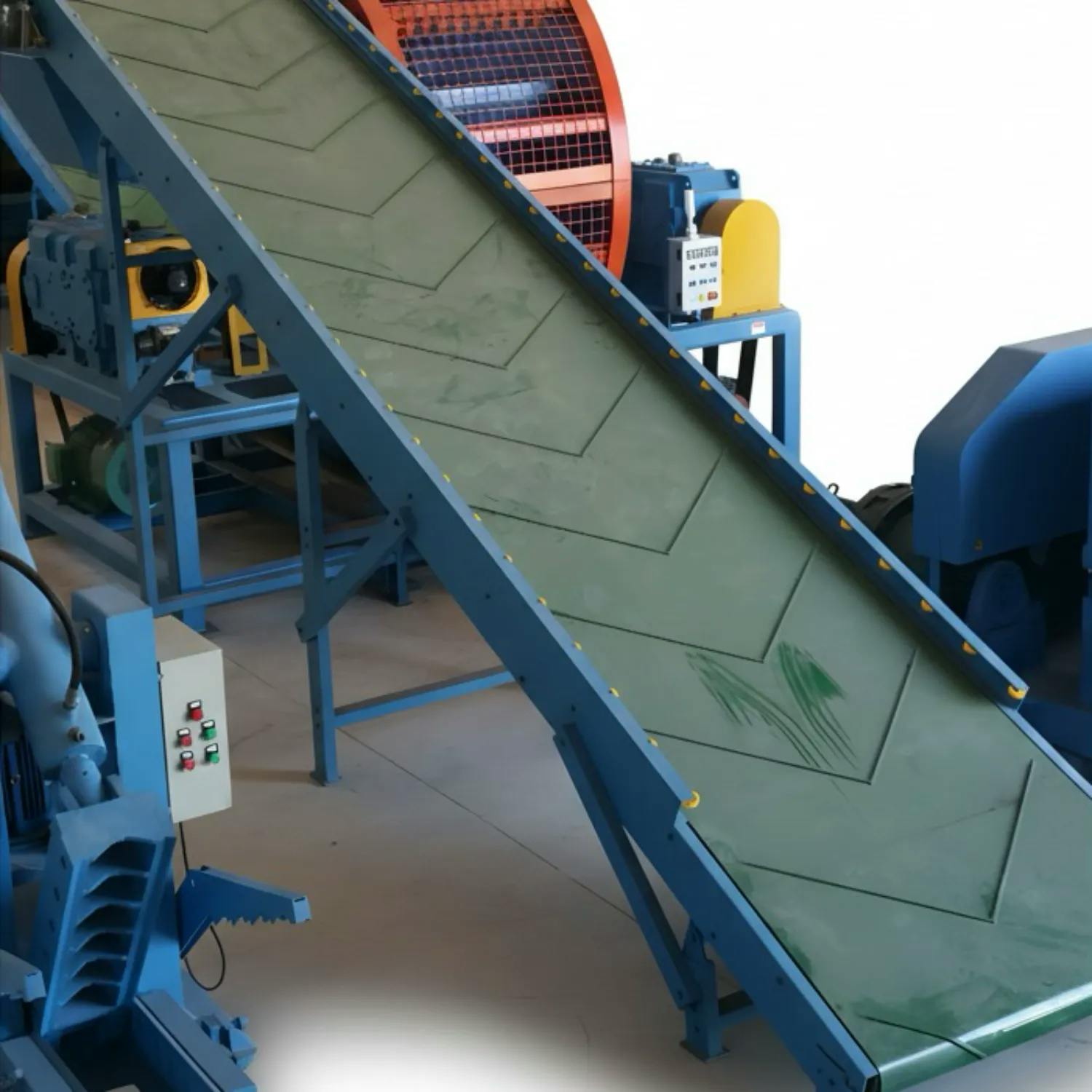

Belt Conveyor

Our heavy-duty Belt Conveyor system is the backbone of the production line, ensuring a smooth and consistent flow of material between processing stages. Engineered for reliability, it automates transportation, minimizes manual handling, and keeps your entire recycling plant operating at peak efficiency.

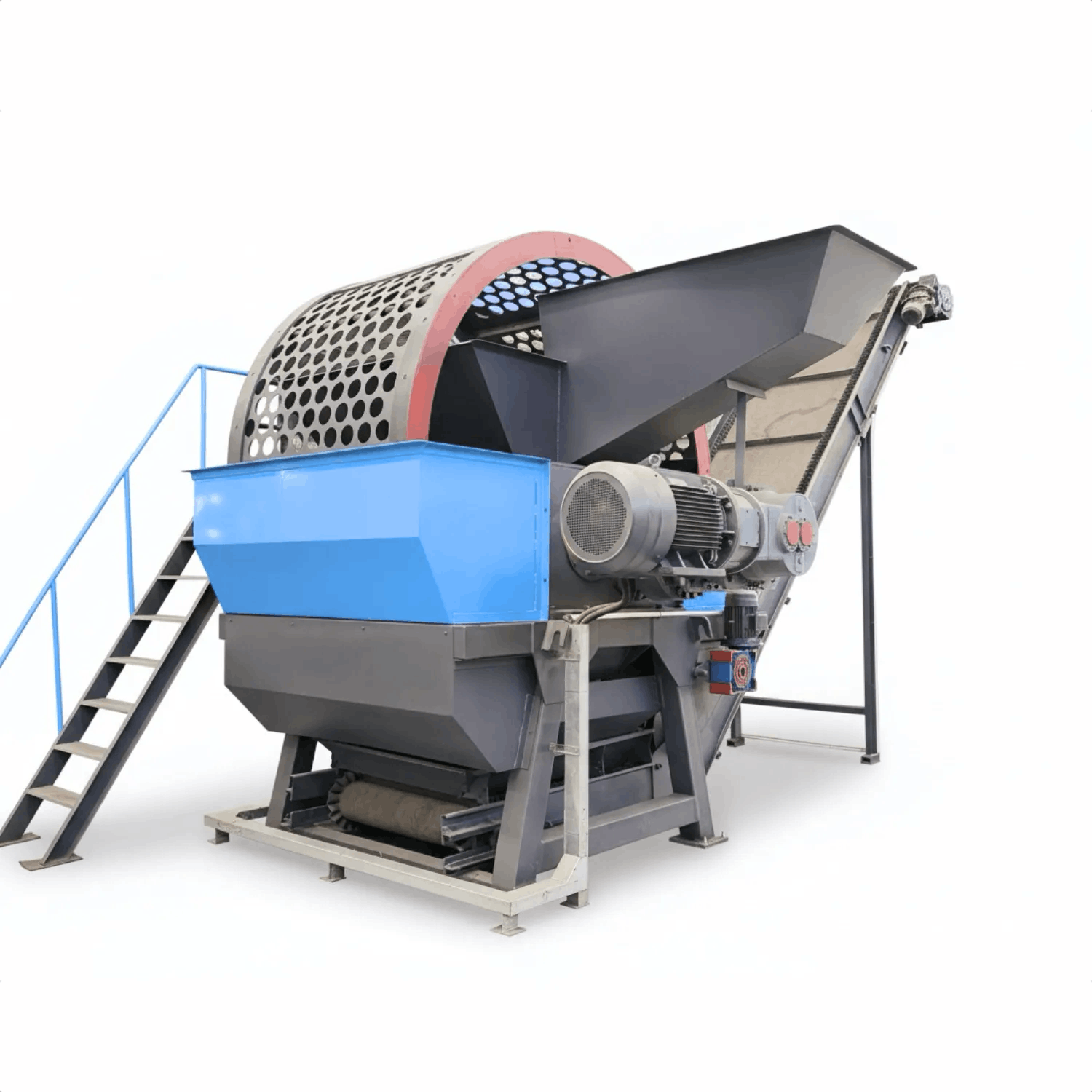

Tire Shredder

At the heart of our system is the high-torque Tire Shredder. This powerful machine is engineered to break down whole, debeaded tires into uniform 50x50mm rubber chips with exceptional efficiency. Its robust, wear-resistant blades and advanced transmission system ensure reliable performance and high throughput, making it the essential first step in size reduction.

Coarse Fiber Separator

Achieve superior purity in your recycled rubber with our Coarse Fiber Separator. This advanced system uses a powerful air classification process to efficiently remove nylon and textile fibers from the rubber granules. The result is a cleaner, higher-quality end-product, which commands a better price in the market and is suitable for a wider range of applications.

Double Roller Rubber Grinder

The Double Roller Rubber Grinder, or cracker mill, is designed for secondary size reduction, transforming rubber chips into finer granules (e.g., 1-6mm). By utilizing two counter-rotating rollers with a precise speed differential, it effectively grinds and liberates any remaining steel and fiber. This stage is crucial for preparing the material for fine powder production.

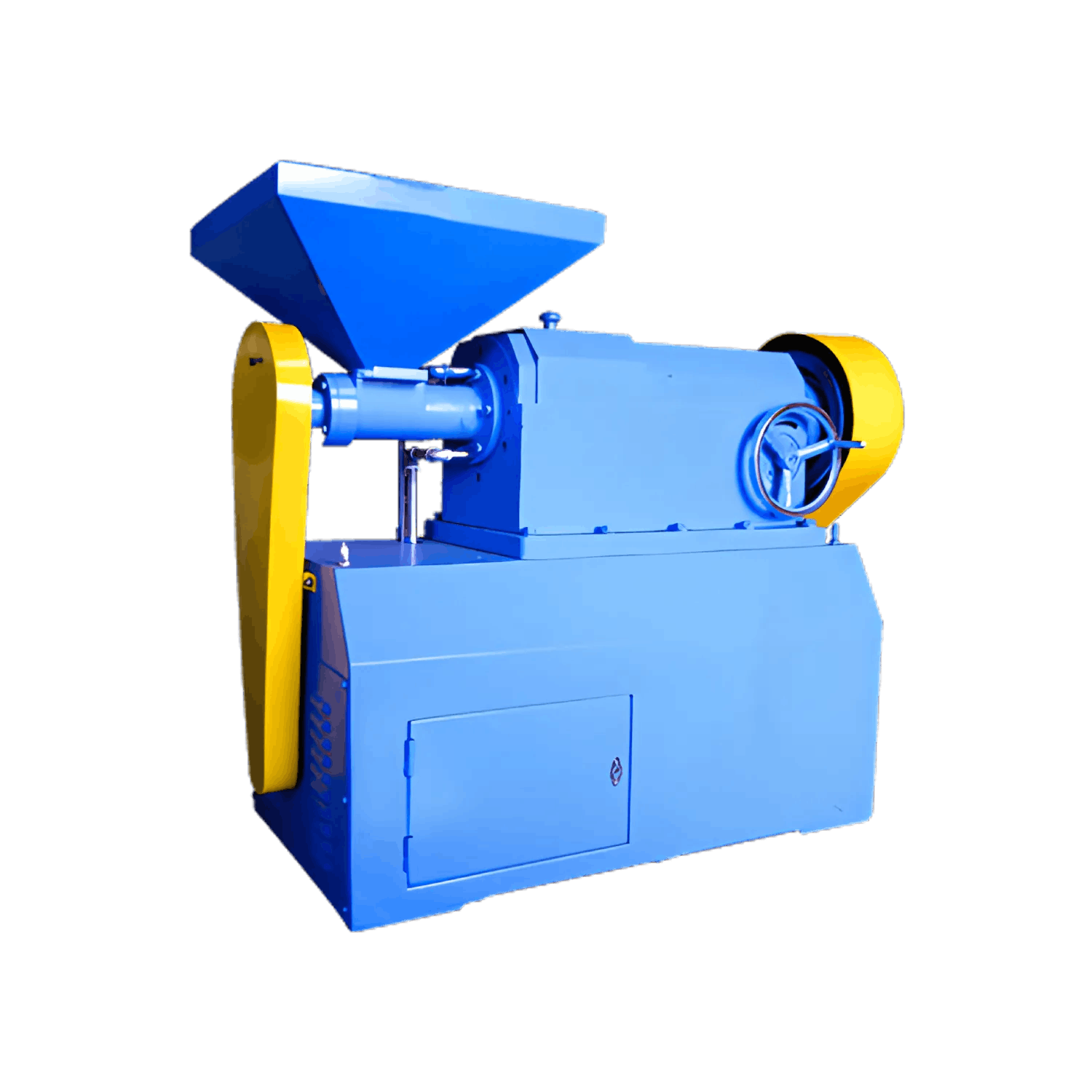

Rubber Powder Superfine Miller

Unlock the highest value from your recycled material with our Rubber Powder Superfine Miller. This state-of-the-art pulverizer transforms rubber granules into fine, high-quality rubber powder (30-120 mesh). The resulting superfine powder is a valuable commodity for manufacturing new rubber products and modifying asphalt, significantly boosting your operation’s profitability.

Rubber Powder Grader

Precision is key to market value. Our Rubber Powder Grader employs an advanced air classification system to accurately sort the superfine rubber powder into specific mesh sizes. This ensures you can meet exact customer specifications and consistently deliver a high-grade product, maximizing the marketability and value of your output.

Screw Conveyor

Our enclosed Screw Conveyor provides a clean, efficient, and contained method for transporting rubber granules and powder throughout the plant. It prevents material loss and contamination, ensuring a tidy and safe operational environment while seamlessly connecting different processing stages.

PLC Auto Control System

Take full command of your recycling plant with our centralized PLC Auto Control System. Featuring a user-friendly interface, this intelligent system monitors and manages every component of the production line in real-time. It optimizes performance, enhances safety with automated diagnostics, and allows for one-person operation, dramatically reducing labor costs and simplifying plant management.

Cooling System

High-performance grinding generates heat. Our integrated Cooling System is vital for maintaining optimal operating temperatures, especially for the fine milling stages. By efficiently circulating cooling water, it prevents rubber from overheating, ensures consistent powder quality, and protects critical machine components from heat-related wear, guaranteeing the longevity and reliability of your entire system.

Your Questions Answered

What is a Tire Recycling Machine?

A Tire Recycling Machine, also known as a tire recycling plant, is a set of equipment designed to process end-of-life tires (ELT) into reusable materials like crumb rubber, steel, and fiber, preventing them from ending up in landfills.

What is the profit from recycling tires?

The profitability of tire recycling depends on market prices for the end-products. The main revenue comes from selling crumb rubber, reclaimed steel, and tire-derived fuel (TDF). Our system is designed to maximize the yield of these materials, thus enhancing your potential profit.

What types of tires can be processed?

Our versatile tire recycling line can efficiently process various types of tires, including passenger car tires, truck tires, and OTR (off-the-road) tires, turning them into valuable resources.

Is the operation of the machine safe?

Absolutely. The entire production line is designed with multiple safety features, including emergency stops, protective guards, and an automated PLC control system to protect operators and ensure a safe working environment.

What is the setup cost for a tire recycling plant?

The total investment depends on the required capacity and level of automation. We offer scalable solutions to fit different budgets and business goals. Please contact us for a detailed quote tailored to your specific needs.

Where can I purchase a Tire Recycling Machine?

You can purchase a complete tire recycling plant or individual components directly from us. Contact our sales team via the form below for expert consultation and to begin the purchasing process.

Get a Custom Quote Today

Ready to turn waste into wealth? Let our experts design a custom tire recycling solution that fits your business goals and budget. Contact us now for a free, no-obligation proposal.